Attention to detail

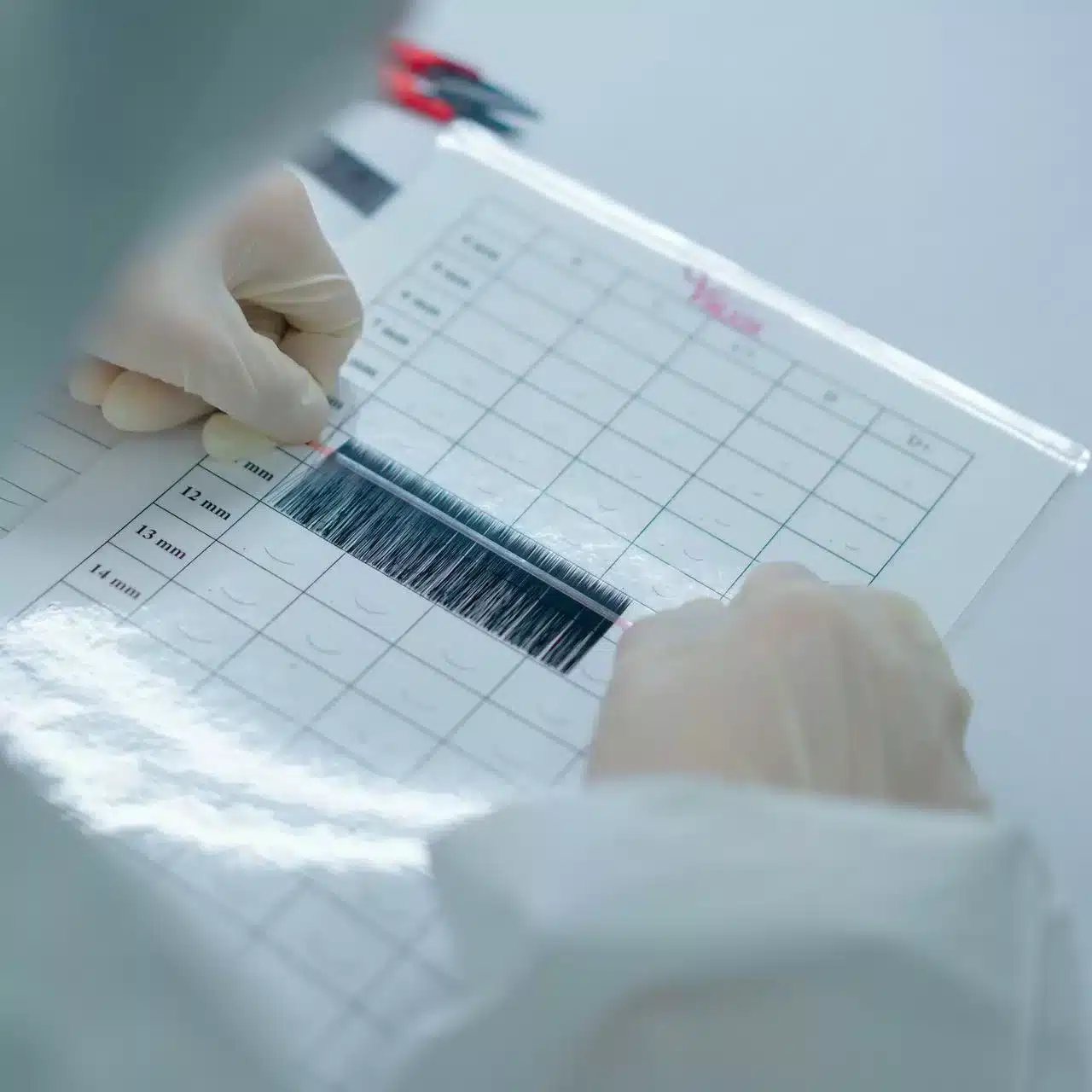

At Vinlash, we believe that every detail matters. Our skilled craftsmen meticulously handle each lash product, ensuring precise placement and alignment of lash fibers.

Consistency

We maintain consistent craftsmanship across our entire lash product range. Our craftsmen adhere to strict quality standards, ensuring that each lash extension meets our precise specifications.

Fine-tuned techniques

With years of experience, our craftsmen have mastered various techniques and possess the expertise needed to deliver meticulous craftsmanship in every lash product.