Discover expert tips to handle shock polymerization lashes like a professional. Learn how to prevent, identify, and remedy clumpy lashes effectively.

Ever wondered why sometimes lash glue seems to dry up or harden too quickly, making the process a bit tricky? That’s what we’re exploring here! Shock polymerization lashes happen when the glue unexpectedly hardens faster than expected, and it can throw a bit of a curveball during the application process. But fear not! We’ll uncover what causes this sudden hardening, why it matters to lash technicians, and most importantly, how to prevent it. So, let’s untangle the mystery behind shock polymerization in lashes together!

Contents

Understanding Shock Polymerization Lashes

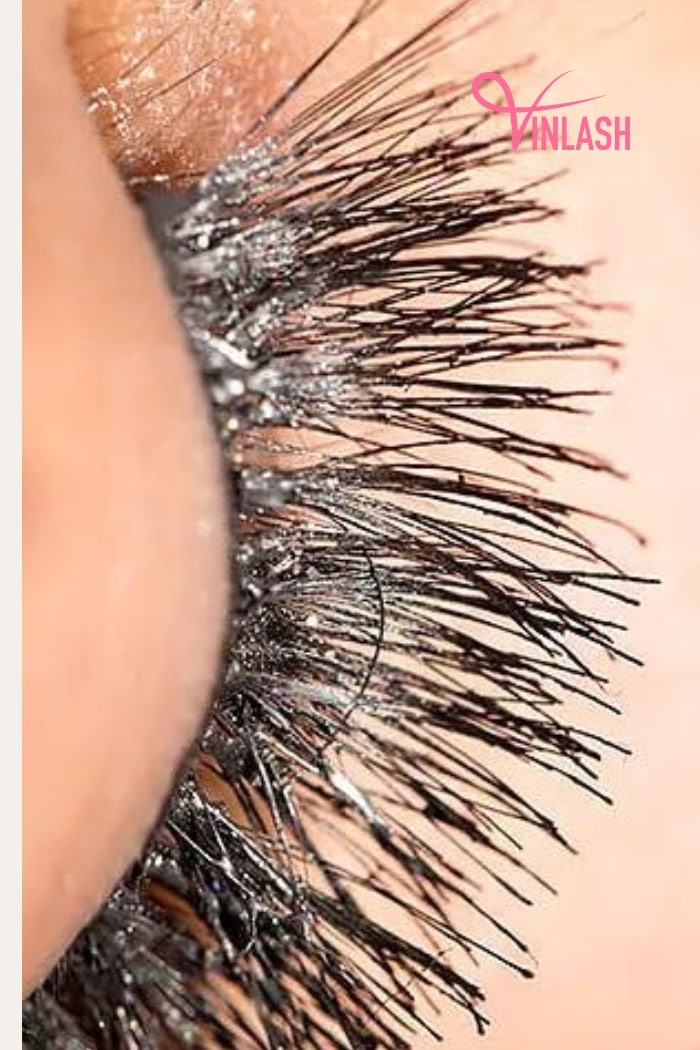

Shock Polymerization Lashes occur when lash extension glue rapidly and unexpectedly dries, leading the adhesive color to shift from black to white. Think of it like when your hair suddenly tangles – only this time, it’s with lashes extensions!

Understanding Shock Polymerization Lashes

This rapid hardening can occur for several reasons, such as sudden contact with moisture, high temperatures, or when using old or expired glue.

Keep reading to uncover more about the symptoms and the causes behind shock polymerization

Symptoms and Identification of Shock Polymerization Lashes

When eyelash extensions experience shock polymerization, they might show some signs that are a bit like a surprise hiccup!

Here’s what to look out for:

- Clumpy Lashes: Instead of beautifully separated lashes, shock polymerization lashes unexpectedly stick together in groups, like tiny lash parties happening on your eyelids.

- Lash Glue Turns White: Sometimes, the lash glue might unexpectedly turn white, which can indicate that the lashes have clumped together suddenly. It’s like a surprise change in color that shows something might not be quite right with the way the lashes are sticking

- Possible Discomfort: Sometimes, these clumps might feel a tad heavier or slightly uncomfortable in your eyes, like having a bunch of guests crowded in one corner at a party.

Knowing these signs helps you spot if lash extensions have had a surprise bonding session and lets you take steps to fix or prevent it for a more comfortable and beautiful look.

Reasons causing shock polymerization lashes

Here are some friendly and easy-to-understand reasons that can cause shock polymerization:

- Moisture Mishaps: When there’s too much moisture during the lash extension process, like sweat or high humidity, it can make the lash glue act unexpectedly, causing lashes to suddenly stick together in clumps.

- Temperature changes: Changes in temperature or humidity levels where the extensions are applied can affect how the glue behaves. These shifts might cause lash extensions to bond suddenly, leading to shock polymerization.

- Glue Issues: If the lash adhesive isn’t applied correctly or doesn’t bond properly, it can lead to sudden sticking of lashes, resulting in clumping and uneven distribution.

- Rushed Application: Sometimes, if the lash technician is in a hurry or doesn’t isolate the lashes correctly during application, it can cause lash extensions to bond haphazardly, resulting in shock polymerization lashes.

- Incorrect Aftercare: Improper aftercare, like getting the lashes excessively wet too soon after application, might disrupt the bonding process and contribute to shock polymerization.

Understanding these reasons helps both you and your clients avoid shock polymerization, ensuring that lash extensions look fabulous and feel comfortable!

How To Get Rid of Shock Polymerization

Shock polymerization, often caused by sudden temperature changes or improper handling, can affect the quality of materials for your clients.

How To Get Rid of Shock Polymerization

Removing shock polymerization for your clients involves several steps to ensure a smooth process:

- Consultation and Examination: Carefully examine the lashes for any signs of shock polymerization such as irritation, redness, or rapid lash loss.

- Discussion and Explanation: Explain shock polymerization lashes, its causes, and how it might be affecting the client’s lash extensions. Also, encourage the client to share any discomfort or specific issues they’re facing.

- Adjustment of Lashes: If the shock polymerization is severe, discuss the option of removing the lashes. Use a suitable lash adhesive remover or solution to gently dissolve the adhesive and remove the extensions without causing further irritation.

- Aftercare Recommendations: Advise the client to gently cleanse the eye area using a mild, oil-free cleanser to maintain hygiene without aggravating the skin.

- Schedule a Follow-Up: Arrange a follow-up appointment to monitor the progress and ensure the client’s lashes are healing properly.

- Client Education: Ensure clients understand the causes of shock polymerization and how to prevent it in the future.

Remember, gentle and cautious removal is crucial to avoid additional discomfort or injury for your clients.

Tips to Prevent Shock Polymerization

Vinlash manufacturer can provide you some tips to help prevent shock polymerization for lash technicians:

Tips to Prevent Shock Polymerization

- Ideal Conditions: Maintain a controlled environment with consistent humidity and temperature during lash application to prevent rapid adhesive curing.

- Quick Application: Work efficiently and swiftly during the lash extension process to reduce the exposure time of the adhesive to air.

- Drop Technique: Use minimal adhesive and employ the drop technique to control the amount applied, reducing the risk of excessive curing.

- Isolation: Ensure lash isolation techniques of natural lashes to prevent adhesive contact with the skin, minimizing chances of shock polymerization lashes.

- Use Fresh Adhesive: Replace adhesive regularly according to the manufacturer’s recommendations to maintain its efficacy.

- Technique and Practice: Enhance your technique through practice and training to apply lashes efficiently, minimizing exposure time.

Implementing these measures can significantly reduce the risk of shock polymerization, ensuring a smoother and safer experience for both the technician and the client.

>> See more: Guide To Deal With Allergic Reaction to Eyelash Extensions

Conclusion

Understanding shock polymerization lashes can make a world of difference for both lash technicians and clients. By knowing what causes this quick hardening of lash glue and how to prevent it, the lash application process becomes smoother and more comfortable. Remember, maintaining the right environment, using fresh glue, and working efficiently with eyelash glue suppliers is key to keeping shock polymerization at bay. So, armed with this knowledge, lash technicians can ensure a seamless and enjoyable lash extension experience for everyone involved.

Now, go forth and lash on confidently, knowing the secrets to tackling shock polymerization like a pro!